Gateway Arch

Contents |

[edit] Introduction

The Gateway Arch is a structural expressionist monument located on the west bank of the Mississippi River in St. Louis, Missouri. It was built as a monument to the westward expansion of the United States. At 192 m (630 ft) in height, it is the world’s tallest arch, and the tallest man-made monument in the Western Hemisphere.

The idea was conceived as part of the Jefferson National Expansion Memorial (JNEM), created in 1935. A nationwide design competition was held in 1947/48 and Ero Saarinen’s arch was chosen as the winner. Since its completion in 1965, it has become a popular tourist attraction and a defining symbol of the city of St. Louis.

[edit] Design

Eero Saarinen conceived of the monument as being clad in stainless steel and built in the form of an inverted, weighted catenary arch, a shape such as would be formed by a heavy chain hanging freely between two supports.

The arch spans 192 m (630 ft) between the outer faces of its triangular legs. Each leg is an equilateral triangle, narrowing from 16 m (54 ft) per side at the bases to 5.2 m (17 ft) at the top. Complex mathematical equations were required to ensure the arch design would work, and the base of each leg at ground level had an engineering tolerance of just 0.4 mm (1/64 inch) to ensure they would meet at the top.

Each leg consists of a stainless steel skin covering two carbon-steel walls with reinforced concrete sandwiched between them. This continues until 91 m (300 ft), at which point carbon steel stiffeners are used instead of concrete. These inner and outer stressed-skins join to form a composite structure which carries the self weight and wind loads to the ground.

Each leg is embedded in concrete foundations 13 m (44 ft) thick and 18 m (60 ft) deep. The arch is earthquake-resistant and designed to sway up to 46 cm (18 inches) in either direction, while withstanding winds of up to 150 miles per hour.

The arch is hollow and accommodates a tram system that carries visitors from the lobby to an observation deck at the top. Operating at the rate of 340 ft per minute, the ride takes 10 minutes for the full trip. The observation platform is 65 x 7 ft, and fitted with plate-glass windows that provide views to the east and west.

[edit] Construction

Construction was postponed during World War II, and it wasn’t until 1959 that ground was first broken. The foundations were laid in 1961, and the arch construction itself began in 1963 as the first steel triangle for the south leg was moved into place.

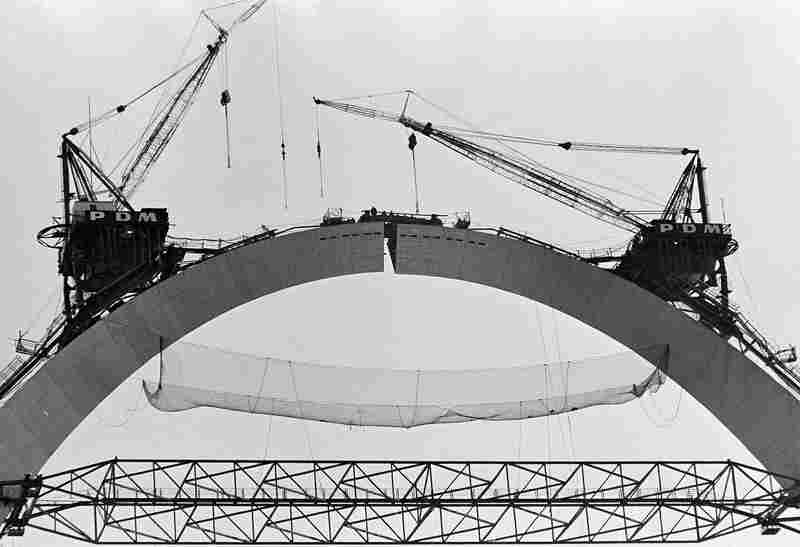

The steel triangles, narrowing as they spiralled to the top, were raised into place using a group of cranes and derricks. Once in place, each section was filled with concrete and prestressed with 252 tension bars. As a means of keeping the partially-completed legs steady, a scissors truss was placed between them at 160 m (530 ft). This was later removed as the derricks were dismantled.

Construction progress was delayed by a combination of funding issues, safety checks and legal disputes. Civil rights activists brought work to a stand-still as strikes were held in protest against the fact that African-American workers, who were being discriminated against, were working on the project.

On October 28 1965, the arch was finally topped out. The keystone was a 2.4 m (8 ft) long triangular section. To mitigate against thermal expansion, which had constricted the gap at the top by 13 cm (5 inches), fire hoses were used to spray water to cool the surface and help it contract. When the keystone was in place, a hydraulic jack was used to pry the legs apart 1.8 m (6 ft), with the final section being inserted to secure the arch.

Having cost $13 million (equivalent to $190 m in 2015), the arch opened to the public in June 1967.

[edit] Find out more

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

Call for greater recognition of professional standards

Chartered bodies representing more than 1.5 million individuals have written to the UK Government.

Cutting carbon, cost and risk in estate management

Lessons from Cardiff Met’s “Halve the Half” initiative.

Inspiring the next generation to fulfil an electrified future

Technical Manager at ECA on the importance of engagement between industry and education.

Repairing historic stone and slate roofs

The need for a code of practice and technical advice note.

Environmental compliance; a checklist for 2026

Legislative changes, policy shifts, phased rollouts, and compliance updates to be aware of.

UKCW London to tackle sector’s most pressing issues

AI and skills development, ecology and the environment, policy and planning and more.

Managing building safety risks

Across an existing residential portfolio; a client's perspective.

ECA support for Gate Safe’s Safe School Gates Campaign.

Core construction skills explained

Preparing for a career in construction.

Retrofitting for resilience with the Leicester Resilience Hub

Community-serving facilities, enhanced as support and essential services for climate-related disruptions.

Some of the articles relating to water, here to browse. Any missing?

Recognisable Gothic characters, designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.